Effect of Nutrient Supplementation on the production of Single Cell Protein from Orange and Banana peel

Anjali Tripathi1, Amulya Musali2, Kartik Uniyal3*, Hridyanshi Mishra1

1Department of Biotechnology, Axis Institute of Higher Education, Kanpur, Uttar Pradesh, India.

2Gandhi Institute of Technology and Management, Visakhapatnam, Andhra Pradesh.

*Department of Biotechnology & Microbiology, Alpine Institute of Management and Technology, Dehradun, Uttarakhand, India.

Abstract

An inexpensive and alternative protein source to address the nutritional need caused by the rapidly expanding population, single-cell protein (SCP) derived from agro-waste material has recently attracted more interest. Also, the environmental problems are diminished by the bioconversion of these wastes into SCP, such as value-added products. The biological reformation of fruit debris into single-cell protein via microbial fermentation can resolve the world’s protein deficit in the diet. This single-cell protein has the potential to be a cost-effective food product ingredient. The dumping of fruit waste in landfills can threaten the health of life forms. Taking this into account, the current study sought to investigate the utilization of fruit wastes in conjunction as a source to produce single-cell protein. Using fruit waste as a foundation for the creation of high-nutritional packaged foods, as well as, reducing surrounding squander. In the proposed investigation, Saccharomyces cerevisiae was cultured on two different fruit trash such as banana skin, and orange peel, waste to yield single cell protein. Microbe protein is inexpensive, accessible to get in rudimentary form, nutritious, and can be released publicly as a feedstuff in addition to boosting its nutrient benefit.

Keywords: Fermentation; Fruit waste; Saccharomyces cerevisiae; Single cell protein

Corresponding Author

Kartik Uniyal

Email: kartikuniyal09@gmail.com

- Introduction

Proteins are a significant dietary component for nitrogen and sulphur delivery and are a major frameworkelement that gives the body its mechanical support. They are essential for the normal growth and development of all living things. Their shortfall can cause a variety of health problems like Kwashiorkor and Marasmus, prevalent in impoverished persons (Dunuweera et al., 2021). Malnutrition affects a huge portion of the world’s population, particularly those living in poverty. There is a significant disparity between the demand for protein-rich foods and the supply of such foods to the world’s ever-growing inhabitants (Yousufi and Khan, 2012). The global protein deficit has recently become a source of concern. Enhanced protein demand prompted a hunt for innovative and less expensive protein supplements than traditional protein sources. One of the alternatives proposed to address world protein needs is Single Cell Protein (SCP) or microbiological protein (Thiviya et al., 2022; Salazar-López et al., 2022). SCPs can be utilized as a dietary supplement for people or as livestock feed. Single-celll proteins are beneficial since they are microorganisms that grow quickly and produce biomass in a brief span of time (Ribeiro et al., 2022). Single-cell protein production uses a variety of microbes mostly from bacteria like Flavobacterium species, Pseudomonas species Thermomonospora fusca, Lactobacillus species fluorescent, etc. (Saeed et al., 2020); some yeasts namely Saccharomyces species, Torulopsis species, Pitchia species, Candida species, (Attia et al., 2003); algae like spirulina and blue-green algae ((Saeed et al., 2020) and fungal species of Tricoderma viridae, Fusarium graminaerum, Penicillium cyclopium, and a variety of other filamentous fungi (Saeed et al., 2020). The current work is based on the comparative analysis on effect of nutrient supplementation on production of Single Cell Protein from Orange and Banana peel owing toexistence of significant elements that can be employed in pharmacological and medicinal applications (Hasija et al., 2015; Chung et al., 2018; Behiry et al 2019 & Hanafy et al., 2021).

2. Materials & Methods

2.1. Collection of Fruit samples (Orange and Banana)

Orange and Banana fruit peels were procured in antiseptic containers from a local market at Mohali, Punjab. Soot particles were eradicated from these wedges by delicately soaking them with distilled water. After that, the peels were detached and sun-dried (Fig.2.1.).

2.2. Pretreatment of the Peels

In a 600 C oven, the partially dried peels were completely dried. After drying in the oven, the specimens were blended to powder with an electrical miller and sieved with a 2mm mesh sieve. As a result, the ground samples were sealed in clear polythene bags and kept at ambient temperature.

2.3. Formulation of Microbial Culture

Saccharomyces cerevisiae, a fungus procured from Rapture Biotech International Private Limited, Mohali, Punjab was utilized to ferment fruitpeels. To monitor proliferation,a loop portion of yeast colonies was inoculated into the Potato dextrose broth and incubated for 24 hours in an orbital shaker.

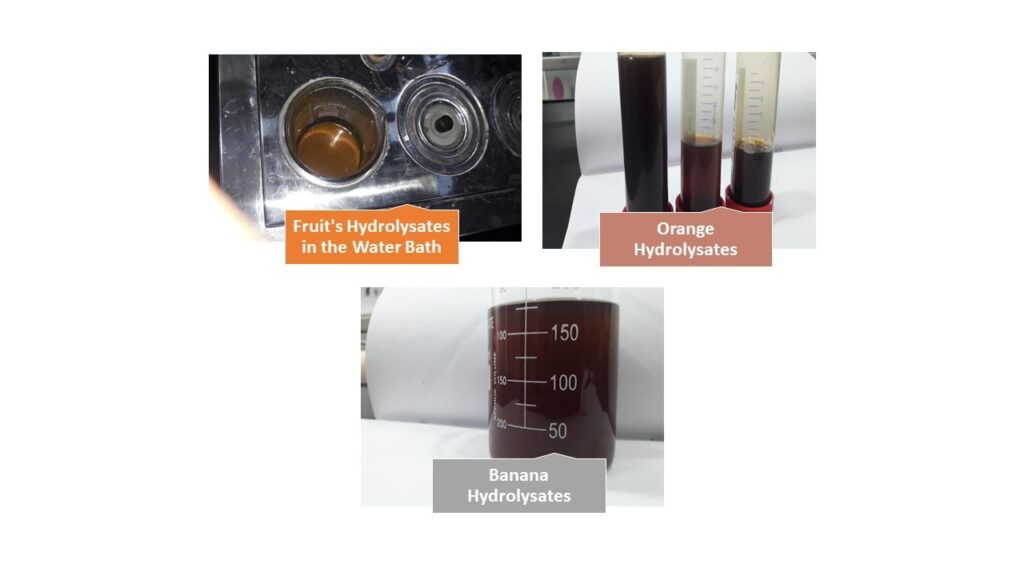

2.4. Preparation of fruit Hydro lysates

Fruit peels were employed as a substrate for the SCP fabrication. Chemical treatments were used to disintegrate peels, so that, it converts cellulose content into more widely accessible sugars, with only minor changes to the (Mondal et al. 2012) process. 50 mL of 10% (v/v) HCL was coupled with 100 mL of distilled water and poured to the peels (20 gms). The solution was then incubated for 1 hour in a water bath at 1000 C (Fig.2). The mixture was then left to cool before being filtered through Whatman No. 1 filter paper. The filtrate was therefore diluted to a final concentration of 10% (v/v) using deionized water. The colonies were kept at 4 °C on a slant of YPDA medium for further research.

2.5. Inoculums Preparation

Inoculums were made using S. cerevisiae cultures grown for four days on YPDA slants and then incubated at 280°C. Different Erlenmeyer flasks containing 98ml of the Basal media were used for submerged fermentation. 2ml S. cerevisiae inoculation (2107cfu/ml) was injected into the media. For 8 days, static fermentation was carried out in a laboratory incubator at 280°C.

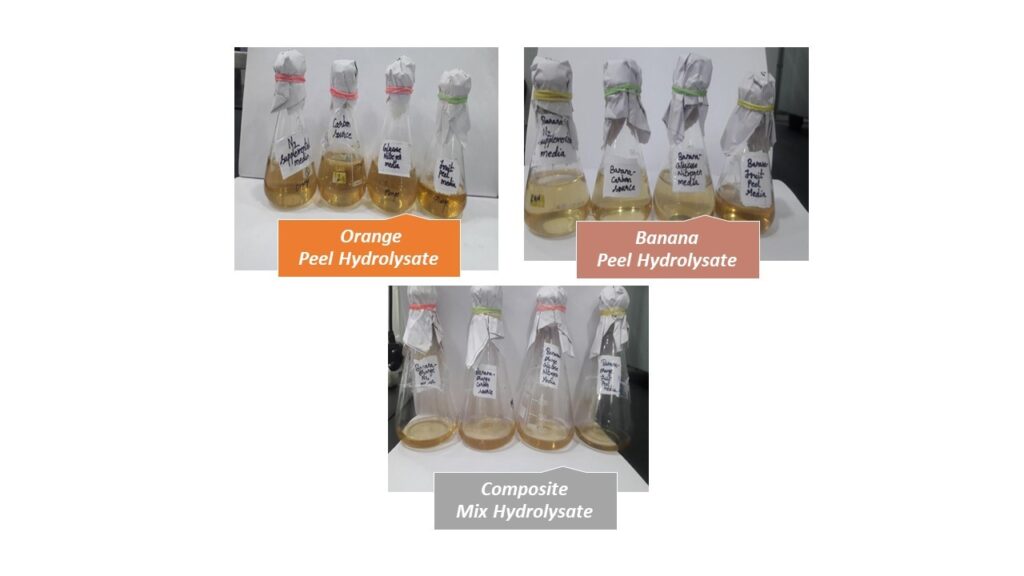

2.6. Fermentation and Collection of Single-Cell Protein

Four experimental mediums were used in submerged fermentations in Erlenmeyer flasks excluding Basal Media. The media were then sterilized using an autoclave at 121°C for 15 min before fermentation. From the 10% fruit hydrolysate, 100 ml was measured and transferred into each medium and the pH was adjusted to 5.5 using 1M NaOH. Thereafter, 2 ml of the prepared inoculum of S.Cerevisiae was transferred into each medium followed by incubation at RT for a period of 8 days (Fig 3). Each of the setup was prepared in triplicate and the average values were calculated.

2.7. Biotransformation of Fruit Waste and proximate analysis of SCP

Media was placed into various Eppendorf after 8 days of fermentation followed by centrifugation at 10,000rpm for 15 minutes. The pellet, together with the Eppendorf tube, was weighed after the supernatant was removed (wet biomass). The protein content of the wet pellet was determined using a chemical analysis. The temperature in the hot air oven was set at 6000 C. The pellet-filled Eppendrof were stored in a preheated oven for 24 hours. The dry weight of the sample was weighed. The method used to determine Moisture, Ash and crude fibre was evaluated according to the AOAC guidelines (2006; AOAC, 2005; method 930.15).

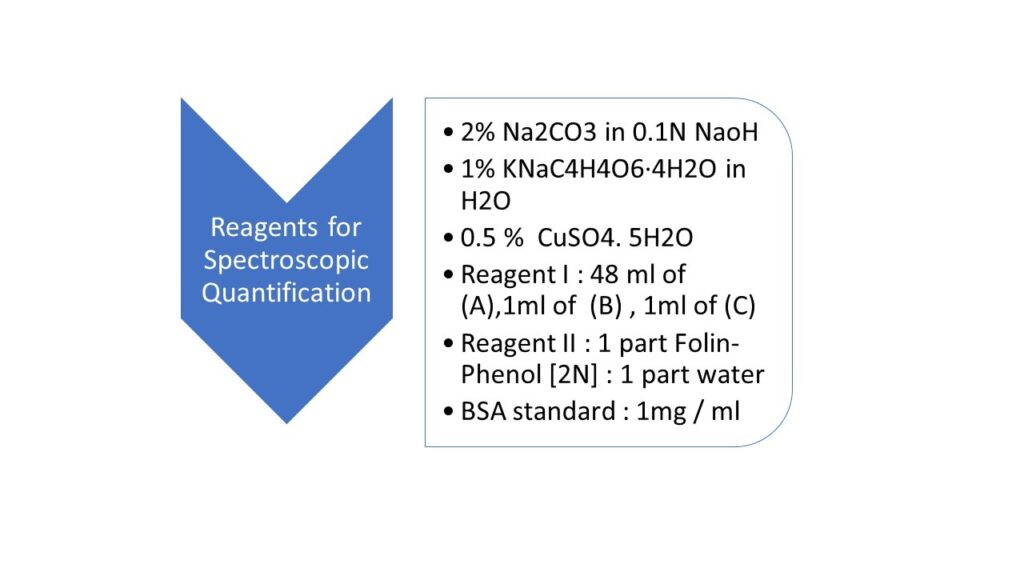

2.8. Spectroscopic Quantification of proteins in contrasting Fruit Hydro lysates

We inserted 30, 60,120, and 240 g/ml of BSA active mixture from the standards in four test tubes and dilute with distilled water to 1ml. Incubated for 10 minutes with 4.5mL Reagent I. Following 30 minutes of incubation, we added 0.5ml of Reagent II and continue to incubate for another 30 minutes (Fig 4).

We designed the standard graph with the absorbance at 660nm. Using the usual graph, estimate the amount of protein present in the given sample.

3. Results & Discussion

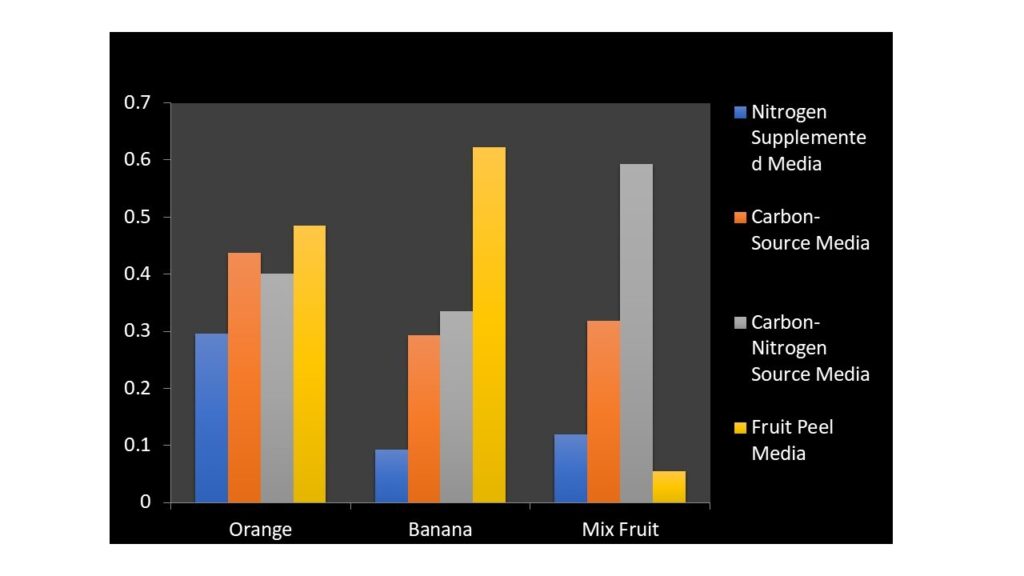

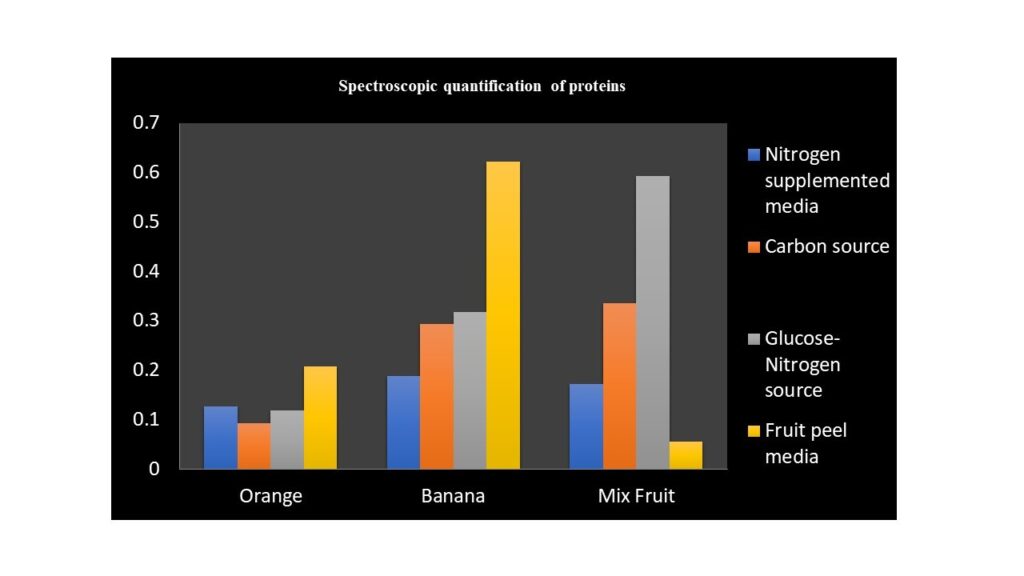

The results of the chemical analysis of the fruit peel extracts were presented in the following figures. The composition of all the waste samples was significantly different for all the tested parameters. The crude protein from the orange peel and Banana peel was found to be of high percentage in the fruit peel media as compared to the other three categories (Carranza-Méndez et al 2022). The crude protein from the Composite mix was high in the Glucose-Nitrogen source (Fig 5).

From the above results it may be said that in comparison, to all the twelve media that were set up, Saccaharomyces cerivisae was more in Banana fruit and as the consequence, crude protein was highest in the Banana fruit peel media that showed that Banana peel alone was itself a great source of protein and could be used widely in the production of SCP. Though orange peel also contained high concentration of carbohydrates but supported less yeast biomass production. This may be due to the less mineral content in orange peels than that of in Banana peels and hence resulted in lower growth of yeast biomass.

3.1. Spectroscopic quantification of protein

Spectroscopic quantification of Protein of all Media observed at 650 nm. The results are shown below (Fig 6).

Figure: 6. Spectroscopic Quantification of Protein

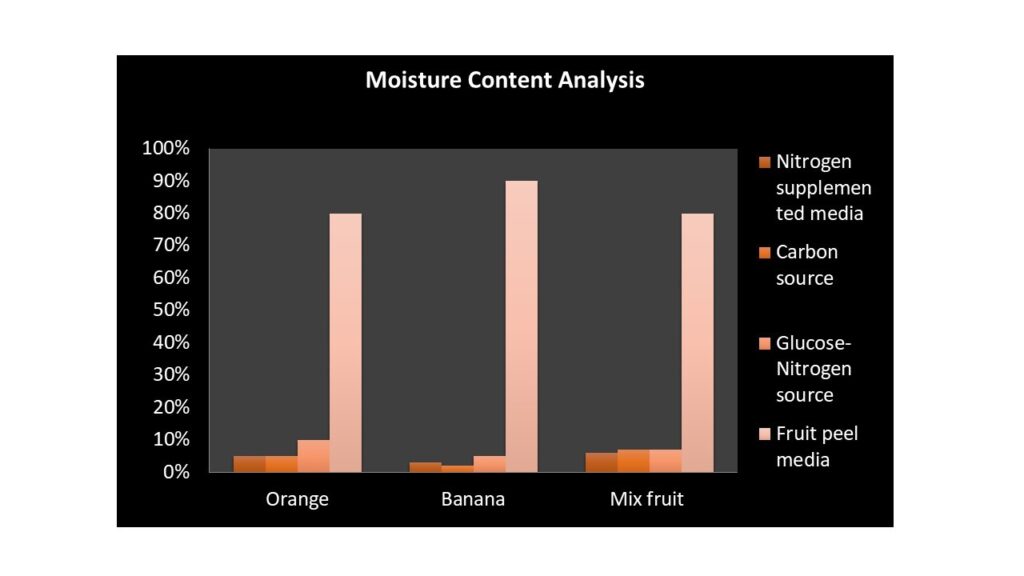

3.2. Analysis of Moisture Content

The processability, shelf life, usability, and quality of a product are all impacted by its moisture content. Hence, determining moisture content accurately is crucial to maintaining quality. According to the above result, we may say that moisture content from the orange peel and Banana peel was found to be of high percentage in the fruit peel media as compared to the other three categories (Fig 7).

The moisture content from the Composite mix was high in the Nitrogen supplemented media.

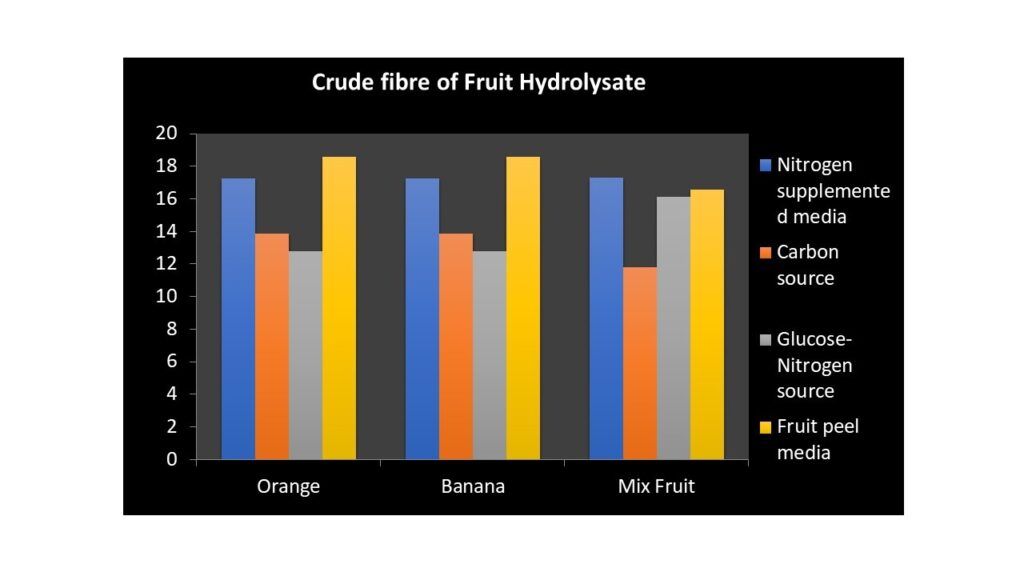

3.3. Crude fibre estimation: –

Non-soluble carbohydrates, often known as “insoluble carbohydrates,” are a type of carbohydrate found in food that is not digested by the digestive juices and does not break down when treated with diluted and concentrated acids and bases. The crude fibre content from the orange peel and Banana peel was found to be of high percentage in the fruit peel media as compared to the other three categories (Fig 8).

The crude fibre content from the Composite mix was high in the Nitrogen supplemented media.

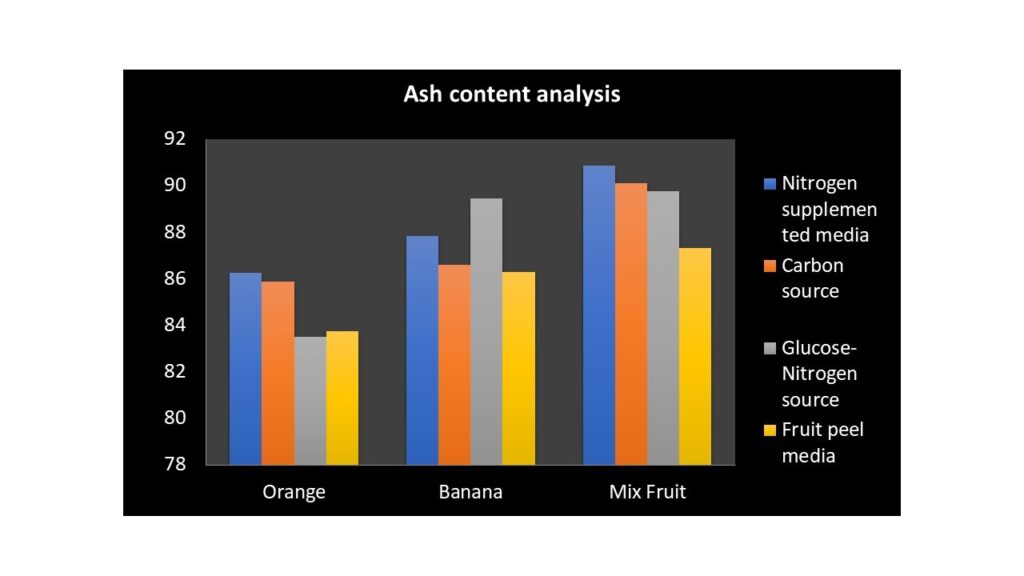

3.4. Ash Content estimation in Fruit Hydro lysate

The ASH content from the orange peel and Composite Mix was found to be of high percentage in the Nitrogen supplemented media as compared to the other three categories (Fig 9).

The ash content from the Banana peel was high in the Glucose-Nitrogen supplemented media.

4. Conclusion

The data obtained in this study indicated that a promising yield of SCP production by S. cerevisiae was achieved by fermentation using banana fruit peels followed by orange peels which are attributed to necessary nutrients being provided by banana peels for the S. cerevisiae to grow and synthesize proteins. Media-rich in Nitrogen source gives the best yields of SCP by banana hydrolysate. The present findings suggested that banana peels can be used as a potential substrate for products with relatively high protein content indicating a scope of converting waste fruit peels to proteinaceous feed and food. Thus, banana fruit peels could be exploited scientifically as a substrate to produce cellular biomass of edible or food-grade yeast instead of dumping them, so that they can be used as animal feed supplements and for human consumption with minimal expense of money.

Acknowledgement

Without the help of my supervisor, this work and the analysis that went into it would not have been feasible. From my initial interaction with the log books of British Naval Ships MS VII.2.77 to the final draught of this dissertation, his zeal, intelligence, and meticulous planning have been an encouragement and maintained my project on track.

Declaration of Interest

There is no competing interest between the authors

Ethical Statement

No animal or human studies has been conducted

Funding Statement

No funding was received

References

AOAC. (2005) (18th ed), 04(31). Official Methods of Analysis for protein, 984(13) p. 2209. Association of Official Analytical Chemists. AOAC.

AOAC. (2005). Official Methods of Analysis for moisture in flour (18th ed), 32:02 p. 2209. Association of Official Analytical Chemists. AOAC 929.03.

AOAC. (2005); 32. Official Methods of Analysis for ash in flour (18th ed). 2209. Association of Official Analytical Chemists. AOAC 929.09.

Attia, Y. A., Al-Harthi, M. A., & El-Deek, A. A. (2003). Nutritive value of undehulled sunflower meal as affected by multienzyme supplementation to broiler diets. Archiv für Geflügelkunde, 67(3), 97–106.

Behiry, S. I., Okla, M. K., Alamri, S. A., El-Hefny, M., Salem, M. Z. M., Alaraidh, I. A., Ali, H. M., Al-Ghtani, S. M., Monroy, J. C., & Salem, A. Z. M. (2019). Antifungal and antibacterial activities of Musa paradisiaca L. peel extract: HPLC analysis of phenolic and flavonoid contents. Processes, 7(4), 215. https://doi.org/10.3390/pr7040215

Chung, D., Cho, T. J., & Rhee, M. S. (2018). Citrus fruit extracts with carvacrol and thymol eliminated 7-log acid-adapted Escherichia coli O157: H7, Salmonella typhimurium, and Listeria monocytogenes: A potential of effective natural antibacterial agents. Food Research International, 107, 578–588. https://doi.org/10.1016/j.foodres.2018.03.011

Hanafy, S., & Magdy, Y. M. A. (2021). El-Shafea, Waled Diaeddeen Saleh, and Hayam Mohamed Fathy. “Chemical profiling, in vitro antimicrobial and antioxidant activities of pomegranate, orange and banana peel-extracts against pathogenic microorganisms.” Journal of Genetic Engineering and Biotechnology 19, 1, 1–10.

Hasija, S., Ibrahim, G., & Wadia, A. (2015). Antimicrobial activity of Citrus sinensis (Orange), Citrus limetta (Sweet lime) and Citrus limon (lemon) peel oil on selected food borne pathogens. Int. J. Life Sci. Res, 3(3), 35–39.

Mondal, A. K., SenGupta, S., Bhowal, J., & Bhattacharya, D. K. (2012). Utilization of fruit wastes in producing single cell protein. International Journal of Science, Environment and Technology, 1(5), 430–438.

Yousufi, M. K. (2012). To determine protein content of single cell protein produced by using various combinations of fruit wastes and two standard food fungi. International Journal of Advanced Biotechnology and Research, 3(1), 533–536.